Introduction

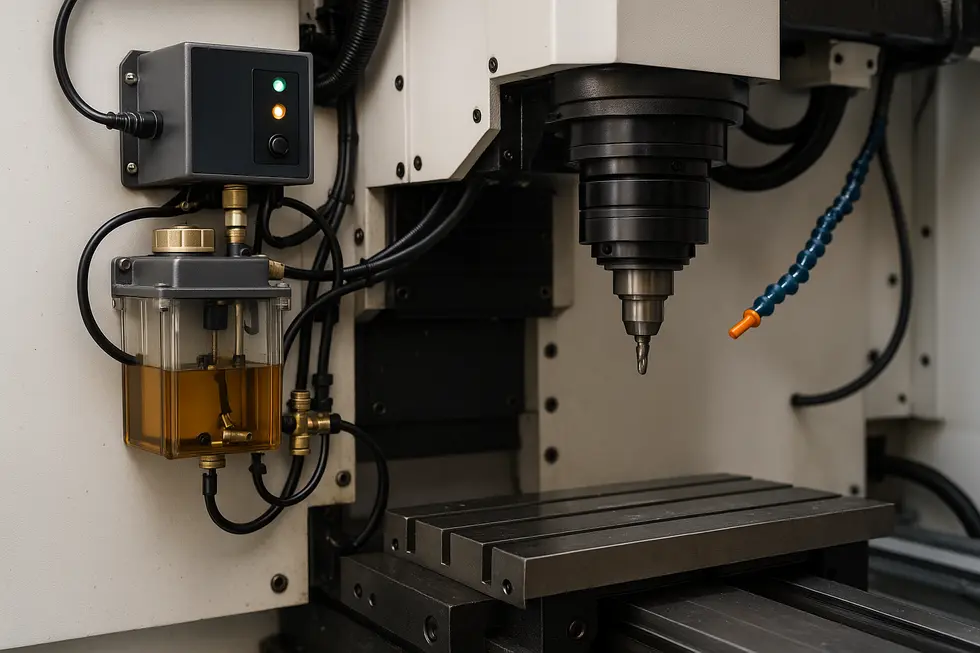

In the realm of CNC machining, where precision is paramount, lubrication stands as a pivotal component that significantly influences machine performance and longevity. Lubricating CNC machines not only enhances precision by reducing friction and ensuring smooth operation but also extends their lifespan by minimizing wear and preventing overheating. The integration of advanced lubrication systems further revolutionizes operations by boosting efficiency and reducing downtime. This comprehensive guide delves into the indispensable role of lubrication in CNC machining, elucidating its impact on precision, longevity, and operational efficiency.

Tables of Contents

Chapter 1: Ensuring Peak Performance: The Essential Contribution of CNC Lubrication to Machine Precision

- Lubrication Dynamics: Unlocking CNC Precision and Longevity

- Harnessing Technology: Advanced Lubrication Systems Driving CNC Precision

Chapter 2: Ensuring Peak Performance: How CNC Lubrication Extends Machine Longevity and Reliability

- Lubrication’s Critical Impact on CNC Efficiency and Precision

- Precision in Motion: The Pivotal Role of Automated Lubrication Systems in CNC Longevity

Chapter 3: Ensuring Peak Performance: Advances in CNC Automatic Lubrication Systems for Enhanced Operational Efficiency

- Revolutionizing CNC Operations: The Unmatched Benefits of Automatic Lubrication

- Optimizing Efficiency with Diverse CNC Lubrication Solutions

Chapter 1: Ensuring Peak Performance: The Essential Contribution of CNC Lubrication to Machine Precision

1. Lubrication Dynamics: Unlocking CNC Precision and Longevity

Lubrication is pivotal to the flourishing operation of CNC machines. By reducing friction between key components like bearings and spindles, lubrication mitigates wear and prevents overheating, essential for sustaining machine accuracy and durability. The intricate design of CNC systems benefits immensely from progressive lubrication systems, which employ divider valves to deliver precise doses of lubricant to multiple critical points. This sophisticated method ensures each part receives exactly what it needs, thus, avoiding both waste and under-lubrication. Automatic systems further enhance this functionality by administering lubrication during machine operation, significantly decreasing downtime while extending component lifespan. Such efficiency not only maintains the quality of outputs but also reduces maintenance costs. Embracing these advanced lubrication mechanisms is crucial for optimizing CNC performance and ensuring consistent product excellence. Learn more about the detailed benefits of these systems at Lubetechnologies.

2. Harnessing Technology: Advanced Lubrication Systems Driving CNC Precision

Modern CNC machining thrives on precision rendered by advanced lubrication systems. These systems, vital for minimizing friction and wear in high-speed operations, are indispensable for maintaining the longevity and accuracy of machine components like spindles and bearings. Centralized lubrication systems automate lubricant delivery to multiple friction points, ensuring all parts receive optimal lubrication. This automation minimizes human error and preserves tight manufacturing tolerances, making it essential for large-scale operations.

Innovations such as supercritical CO₂-based coolants enhance machine performance by combining superior cooling with lubrication, thereby improving thermal management and reducing environmental impact. Systems like these not only improve surface finish quality of machined parts but also curtail maintenance costs, directly supporting the accuracy crucial to industries such as aerospace. Learn more about Fusion Coolant Systems

Chapter 2: Ensuring Peak Performance: How CNC Lubrication Extends Machine Longevity and Reliability

1. Lubrication’s Critical Impact on CNC Efficiency and Precision

In the world of CNC machining, lubrication is not merely a maintenance task; it is a cornerstone of precision engineering. Essential components like spindles and ball screws require optimal lubrication to minimize friction and wear, ensuring prolonged operational life. When lubricants function effectively, they reduce the heat and friction generated during operations, which in turn prevents overheating. This thermal management is crucial, as excessive heat can compromise the integrity of cutting tools, leading to frequent replacements and lowered machining accuracy. Moreover, lubrication aids in maintaining seamless movement and precision, which are pivotal for producing high-quality parts with consistent dimensions. As lubrication also assists in debris removal, it helps prevent scratches and mechanical wear. Thus, it plays a multifaceted role in enhancing the durability and reliability of CNC machines, directly impacting the quality and efficiency of their outputs. For comprehensive advice on CNC lubrication and maintenance, you can refer to resources that delve deeper into equipment longevity and performance optimization at MachineMetrics.

2. Precision in Motion: The Pivotal Role of Automated Lubrication Systems in CNC Longevity

Automated lubrication systems are integral to extending the lifespan and reliability of CNC machines by delivering accurate, continuous lubrication without manual intervention. These systems reduce the risk of human error, ensuring the right amount of lubricant is applied precisely where needed, preventing premature wear and unplanned downtime. Central to their technology are progressive divider valves, expertly distributing lubricant to multiple points from a single pump. Advanced systems utilize programmable logic controllers (PLCs) and integrated controllers for real-time monitoring, ensuring optimal lubrication at scheduled intervals. This precision minimizes maintenance interruptions and supports predictive maintenance strategies by providing actionable insights into system performance, thus maintaining peak operational efficiency. For more insights on lubrication systems, visit Lubrication Systems Overview.

Chapter 3: Ensuring Peak Performance: Advances in CNC Automatic Lubrication Systems for Enhanced Operational Efficiency

1. Revolutionizing CNC Operations: The Unmatched Benefits of Automatic Lubrication

Automatic lubrication systems have fundamentally transformed CNC (Computer Numerical Control) machining by delivering precise and consistent lubrication that’s crucial for machine longevity and performance. By automating this process, these systems eliminate the risks of under and over-lubrication that could lead to machinery wear or lubricant waste. This automated approach significantly enhances operational efficiency by ensuring that CNC machines can continue high-speed operations without unnecessary interruptions for maintenance. Such efficiency not only minimizes downtime but also improves worker safety by reducing the need for manual lubrication in hazardous conditions. Moreover, the cost savings are notable—reduced downtime, decreased lubricant misuse, and prolonged equipment life underscore the financial and environmental benefits. For a deeper dive into the importance of CNC maintenance, see The Importance of CNC Machine Maintenance.

2. Optimizing Efficiency with Diverse CNC Lubrication Solutions

In the realm of CNC machinery, the nuances of lubrication systems play a pivotal role in operational efficiency. Single Line Progressive Lubrication Systems are renowned for their sequential lubricant delivery through metering valves, ensuring even distribution and reducing under-lubrication risks. On the other hand, Parallel Lubrication Systems offer redundancy with multiple circuits, ideal for complex CNC setups where system integrity must remain uncompromised. Specialized technologies like Mist Lubrication Systems, provide minimal yet continuous lubrication, utilizing atomized oil for bearings, while Recirculating Oil Systems ensure a consistent oil circuit for critical components. The choice of system—whether multi-port, mist-based, or minute volume—depends on CNC complexity, precision needs, and maintenance conditions. Leveraging such diverse solutions facilitates sustained precision and machinery longevity. For more on lubrication systems, see Progressive Lubrication Systems.

Final thoughts

By effectively integrating lubrication into CNC operations, manufacturers can ensure optimal machine performance and extended lifespan. The precision, reliability, and efficiency achieved with adequate lubrication solidify its indispensable role in CNC machining. As technological advances continue to refine automatic lubrication systems, businesses stand to benefit from reduced downtime and enhanced productivity, reinforcing the importance of strategic lubrication practices.

Browse Our CNC Lubricants & Request a Free Quote Today

About us

Wurth Machinery is your comprehensive solution for top-tier woodworking and metalworking machinery and shop supplies. As a committed partner in your metalworking and woodworking journey, we enable quality, efficiency, and convenience through our wide-ranging product portfolio, which includes industry-leading brands such as Blum, SCM, Jet Tools, Castle, Cantek, Rev-A-Shelf, and many others. Our support goes beyond product distribution: we offer 24/7 digital ordering, prompt deliveries from our company-owned fleet, and expert assistance from our highly trained representatives. Our factory-trained technicians also provide machinery installation and maintenance. Plus, with flexible credit options—ranging from in-house financing to leasing and installment payments—we cater to all financial needs. With our steadfast commitment to excellence and presence in over 20 locations across the Western United States, we are more than a supplier—we are your strategic partner. Whether you’re a cabinetmaker, professional woodworker, or architect, we’re dedicated to delivering value that propels your business growth.