Introduction

CNC routers have revolutionized industries by offering precision and versatility. For business owners, homeowners, and hobbyists alike, understanding which accessories can enhance the efficiency and precision of CNC routers is crucial. This guide explores essential tools, such as bits, dust collection systems, collets, advanced software, and specialized accessories, providing insights into boosting your CNC operations’ performance.

Tables of Contents

Chapter 1: CNC Router Bits: Essential Tools for Precision & Efficiency

- Exploring Versatile CNC Router Bits to Enhance Your Craft

- Choosing Optimal CNC Router Bits for Precise and Efficient Machining

Chapter 2: Dust Collection Systems in CNC Routing: Enhancing Precision & Efficiency

- Core Elements of Dust Management in CNC Routing

- Refining CNC Precision and Efficiency with Effective Dust Collection

Chapter 3: Collets and Adapters: Securing Precision & Efficiency in CNC Operations

- Collets: The Cornerstone of Precision and Modern Securing Techniques in CNC Machinery

- Adapters and Compatibility: The Gateway to Precision Clamping in CNC Machining

Chapter 4: Software and Design Tools: Boosting CNC Routing Precision & Efficiency

- Precision Unlocked: The Role of CAD/CAM Software in CNC Routing

- Virtual Validation: The Role of Simulation in CNC Routing

Chapter 5: Advanced CNC Accessories: Specialized Tools to Enhance Precision & Efficiency

- Streamlining Performance: The Role of Plug-and-Play Accessories

- The Role of High-Quality Tool Holders in CNC Precision

Chapter 1: CNC Router Bits: Essential Tools for Precision & Efficiency

1. Exploring Versatile CNC Router Bits to Enhance Your Craft

CNC router bits are indispensable for achieving precision and efficiency in various material processing tasks. Among these, end mills stand out for their versatility, adept at cutting slots and profiles in wood and other materials. V-bits excel in detailed engraving work and creating V-shaped cuts, elevating craftsmanship to its finest. Spiral router bits, available in up-cut and down-cut styles, are crucial for smooth material removal and minimizing tear-out. The range of available options extends further, with specialized bits for cutting aluminum, brass, and complex composite materials, each enhancing both durability and performance for unique applications. For an in-depth understanding of selecting the right bit for your project, visit CNC Learn and Build.

2. Choosing Optimal CNC Router Bits for Precise and Efficient Machining

Selecting the right CNC router bit is pivotal for enhancing both precision and efficiency in CNC machining. The bit’s design directly affects the cut quality, material removal rate, and tool durability. Opt for bits engineered for computer-guided operation, avoiding bearing-guided profiles more suited to hand-held use. The geometry of the bit, particularly flute number and configuration, influences chip load and surface finish; more flutes allow higher feed rates with appropriate RPMs to prevent overheating. Material compatibility also demands attention—different substrates, whether wood, acrylic, or metal, require specific bits to minimize wear and achieve clean cuts. Refer to manufacturer guidelines for proper collet insertion to ensure safety and accuracy. Additionally, take advantage of databases like BitsBits for comprehensive feed-and-speed recommendations, ensuring consistency across diverse projects.

Chapter 2: Dust Collection Systems in CNC Routing: Enhancing Precision & Efficiency

1. Core Elements of Dust Management in CNC Routing

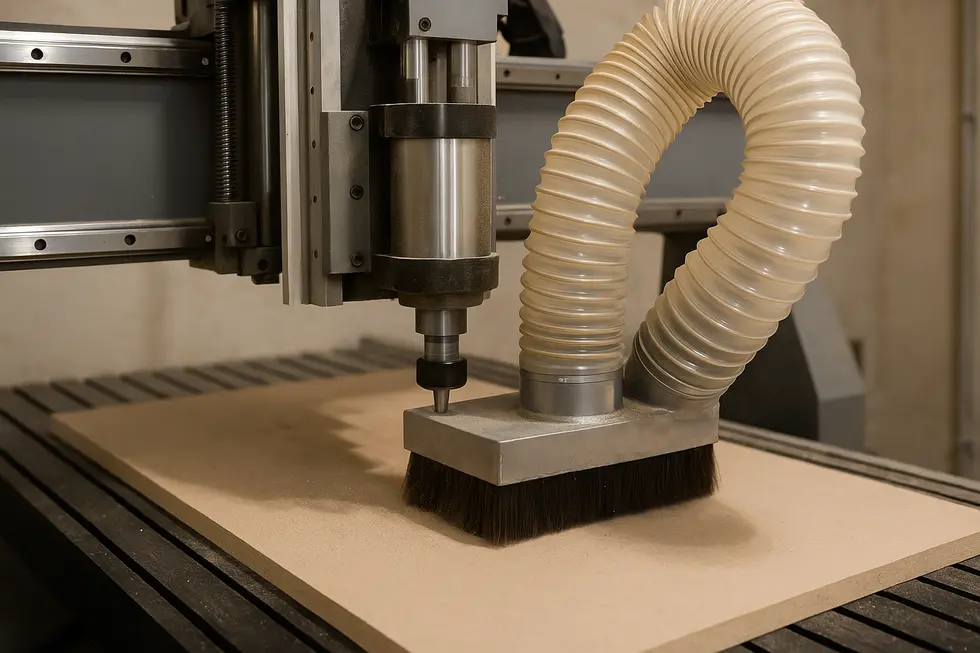

In CNC routing, dust collection systems are indispensable for achieving precision, efficiency, and safety. These systems mitigate the build-up of dust and debris, thereby maintaining clear workspaces and protecting user health. Central to effective dust management are dust collectors, essential for capturing diverse types of dust across operations. Complementing these are ducting systems, which facilitate optimal airflow, ideally with minimal turns to maintain efficiency. Choosing the right ducting is crucial—opt for rigid, modular options to reduce turbulence. Dust extraction accessories like router hoods play a vital role by capturing dust directly at the origin, thus enhancing visibility and reducing cleanup time. For a more detailed guide on optimizing workshops with ducting systems, you can explore this resource.

2. Refining CNC Precision and Efficiency with Effective Dust Collection

CNC routing demands precision, but the process generates dust that can impact both air quality and machine performance. Effective dust collection systems mitigate these issues, capturing dust at its source to maintain a clean work environment. Enclosure-less dust collectors handle high-pressure air systems, targeting fine dust and ensuring the longevity of CNC machines by preventing dust buildup. Systems like the Supercell effectively capture dust across varying tool connections, enhancing performance by maintaining machinery integrity. To optimize these systems, design efficient ductwork with seamless airflow, using rigid ducts, minimal turns, and blast gates. This setup not only preserves equipment precision but also creates a safer, more efficient workspace. For more insights, explore dust collection systems suitable for CNC routers.

Chapter 3: Collets and Adapters: Securing Precision & Efficiency in CNC Operations

1. Collets: The Cornerstone of Precision and Modern Securing Techniques in CNC Machinery

Collets are essential in CNC machining, delivering precision by gripping workpieces uniformly around their complete circumference. This minimizes runout and improves concentricity, vital for high-quality machining. Unlike traditional methods, collets effectively handle various shapes, even complex and custom geometries, enhancing part quality and reducing setup time.

Recent advancements include dead-length operation, where the collet remains fixed as a tapered sleeve compresses it. This feature addresses issues with pullback-style collets, ensuring consistent workpiece positioning, crucial for secondary operations. Moreover, pneumatic and hydraulic systems revolutionize CNC operations by providing even clamping pressure, reducing deformation risks and enhancing precision.

Integrated sensor-based monitoring further optimizes clamping conditions, making collets indispensable for maximizing efficiency and accuracy.

For further insights into CNC collet technology, Understanding CNC Collet Chucks offers comprehensive guidance.

2. Adapters and Compatibility: The Gateway to Precision Clamping in CNC Machining

In CNC machining, precision is paramount, and collet-based clamping systems are central to achieving it. Collets hold cylindrical tools and workpieces using elastic deformation, ensuring minimal runout and high concentricity. Vital for high-speed scenarios, these systems rely on standardized types like 5C and 16C, enabling quick changeovers and machine compatibility while reducing setup time (What is 5C and 16C collet).

Adapters amplify the versatility of collet setups, ensuring seamless integration with different machine spindles. Advanced designs accommodate multiple collet standards, enhancing operational flexibility without sacrificing precision. Furthermore, innovations such as quick-change collets reduce downtime, boosting productivity—a must in modern manufacturing environments.

Chapter 4: Software and Design Tools: Boosting CNC Routing Precision & Efficiency

1. Precision Unlocked: The Role of CAD/CAM Software in CNC Routing

CAD/CAM software stands as a pivotal component in elevating the precision and efficiency of CNC routing. By harmonizing Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), these systems allow for seamless production operations. CAD tools meticulously design parts, while CAM translates these into precise toolpaths for CNC execution, ensuring that any design updates are swiftly mirrored in the manufacturing setup. This tight integration not only minimizes errors and reprogramming but also enhances precision. Using CAD/CAM, operators can simulate operations, preemptively identifying potential issues, which is invaluable for complex, intricate machining processes. The automation capabilities of CAM software further boost efficiency by generating optimized NC code, thus reducing manual intervention and human error, allowing manufacturers to focus on delivering high-quality, customized outputs efficiently. For more insights on how CAD/CAM software is transforming CNC lathe applications, explore this resource.

2. Virtual Validation: The Role of Simulation in CNC Routing

Simulation technologies integrated into CNC routing systems are revolutionizing precision and efficiency. These tools allow machinists to visualize and test machining processes in a digital environment before physical execution. Using advanced software like Fusion 360 and RhinoCAM, potential collisions and design errors are identified early, reducing material waste and optimizing toolpaths. This proactive approach is essential in high-stakes industries like aerospace, where precision is paramount. Moreover, the integration with CAD/CAM platforms enables seamless transitions from design to production, enhancing workflow efficiency. With cloud-based collaboration tools, designers and machinists can share updates and resolve issues in real-time, minimizing downtime. By adopting these innovations, manufacturers can achieve superior accuracy and productivity, consistently delivering high-quality outputs. Learn more about CNC Software Innovations.

Chapter 5: Advanced CNC Accessories: Specialized Tools to Enhance Precision & Efficiency

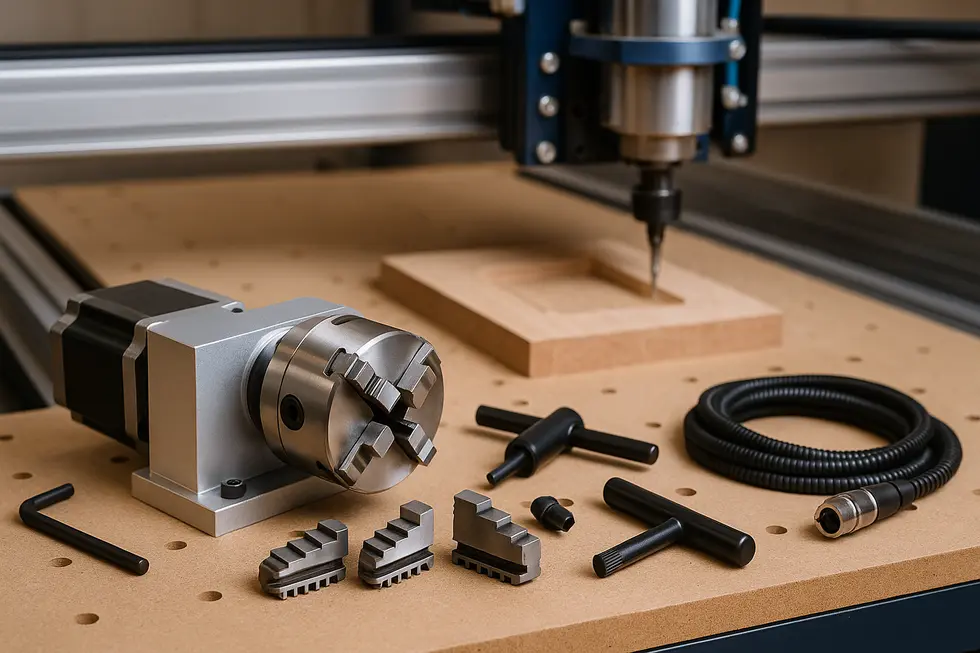

1. Streamlining Performance: The Role of Plug-and-Play Accessories

Plug-and-play accessories are pivotal tools that seamlessly boost the precision and efficiency of CNC operations. These accessories are designed for hassle-free integration, allowing users to amplify machine capabilities without the need for extensive technical know-how or complex setups. For instance, rotary axes enable intricate tasks like engraving and turning, expanding the functional range of CNC machines. The Vortex Rotary Axis by Sienci Labs, known for its user-friendly installation, is a prime example. Similarly, laser systems enhance cutting accuracy, while touch probes aid in precise measurements, supporting higher accuracy and productivity. This ease of use broadens CNC technology’s accessibility, making advanced manufacturing techniques viable for both hobbyists and seasoned professionals alike.

2. The Role of High-Quality Tool Holders in CNC Precision

High-quality tool holders are pivotal in maintaining the precision crucial to CNC operations. By firmly gripping cutting tools, these components minimize runout and vibration, ensuring superior accuracy. Known for their superior grip, shrink-fit holders eradicate tool deflection and slippage, which are key to achieving flawless cuts. Collet chucks and hydro clamping systems also offer precise clamping solutions tailored for various CNC tasks. Precision in CNC is directly proportional to the holders used; those with minimal runout promise tight tolerances. Furthermore, adaptable tool holders like universal angle heads add an axis for versatile machine tool performance, accommodating complex workpieces with ease. For more insights on CNC solutions, visit Hipps CNC Solutions.

Final thoughts

Incorporating the right accessories into your CNC setup can significantly enhance precision and efficiency. From router bits and dust collection systems to collets, software solutions, and advanced accessories, each component plays a pivotal role in optimizing performance. By carefully selecting and integrating these tools, you can achieve superior results in your CNC projects, whether you are a business owner, homeowner, or hobbyist.

Browse Our CNC Router Accessories & Request a Free Quote Today

About us

Wurth Machinery delivers: Extensive Selection: Over 85 CNC routers from top brands such as Cantek, SCM Group, All Star CNC, Powermatic, and more. Flexible Financing & Trade-In: Robust financing programs and trade-in options to fit any budget or equipment-upgrade cycle. Comprehensive Services: Professional installation, full warranty coverage, production-optimization consulting, and post-sale support to keep your operation running smoothly. Expert Consultation: A machinery division staffed by seasoned professionals with deep industrial knowledge to guide project planning and machine selection. Convenient Ordering & Delivery: 24/7 digital ordering paired with prompt deliveries via our company-owned fleet, ensuring you get the right equipment when you need it.